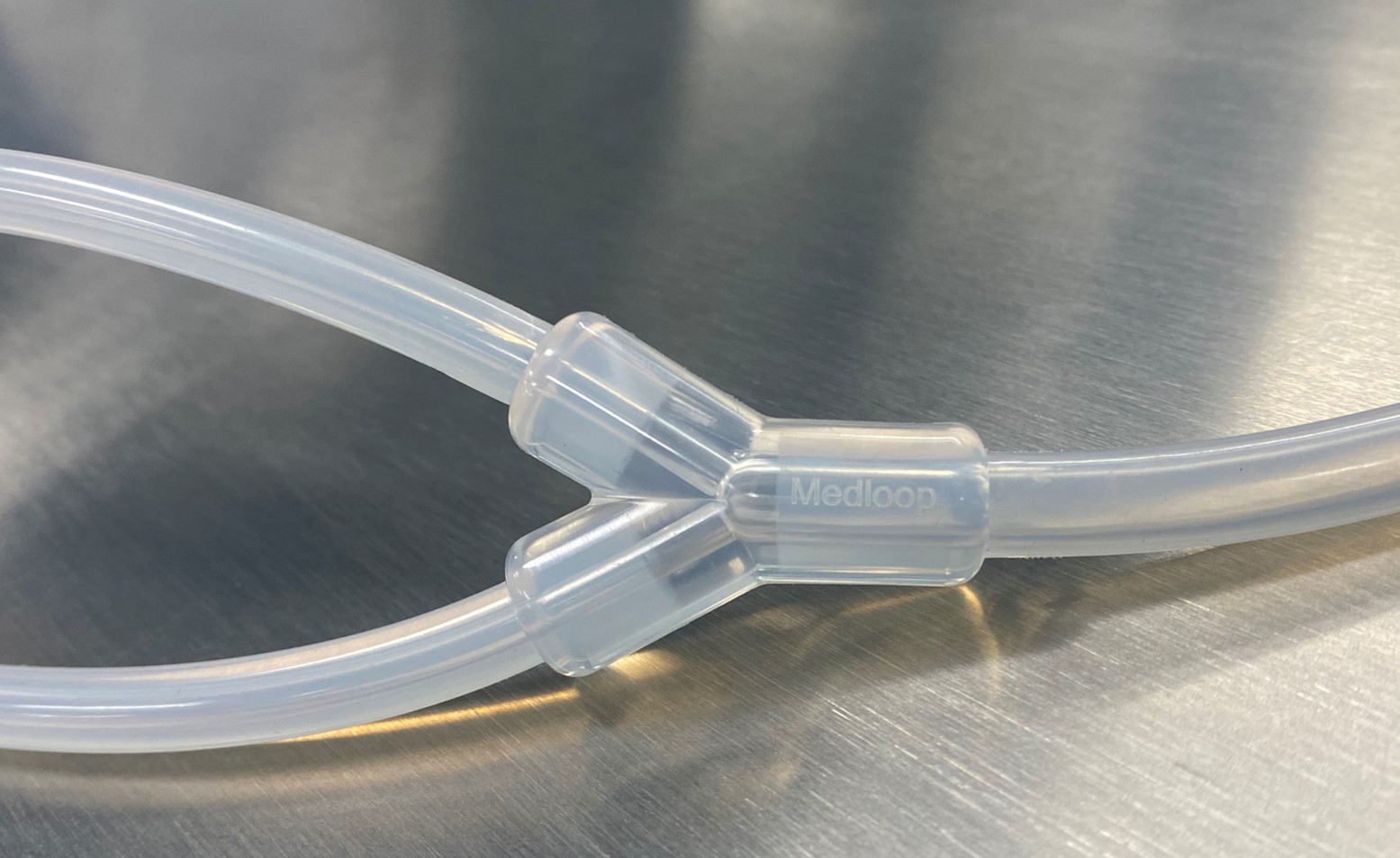

Biopharmaceutical Pt silicone Molded Manifolds

Characteristic Description

Medloop® Platinum Silicone Molded Manifolds are specifically developed for high purity and zero leakage risk applications in biopharmaceutical industry. Its high-purity material formula helps to achieve lower levels of extractables and keep more cleanliness during fluid processing. Its unique fluid channel design can effectively reduce fluid turbulence at the joints, particles residue and fluid leakage risk.

Medloop® Silicone Molded Manifolds are key components in bioprocessing, mainly used for high-temperature steam sterilization, split charging and filling of medicinal liquids and preparations; Medloop® Silicone molded integrated components are the perfect substitute for plastic parts, Its high-temperature resistance is greatly superior to plastic components, Its pressure resistance at the joints is significantly higher than that of plastic fittings and cable ties, the risk of leakage under high pressure tends to zero.

Medloop® products sold is produced and packaged in a 10K class level clean room environment of ISO10993 & ISO13485 quality systems controls, comprehensive batch control is implemented from raw material receipt to finished products delivery.